MS-CTX-DN

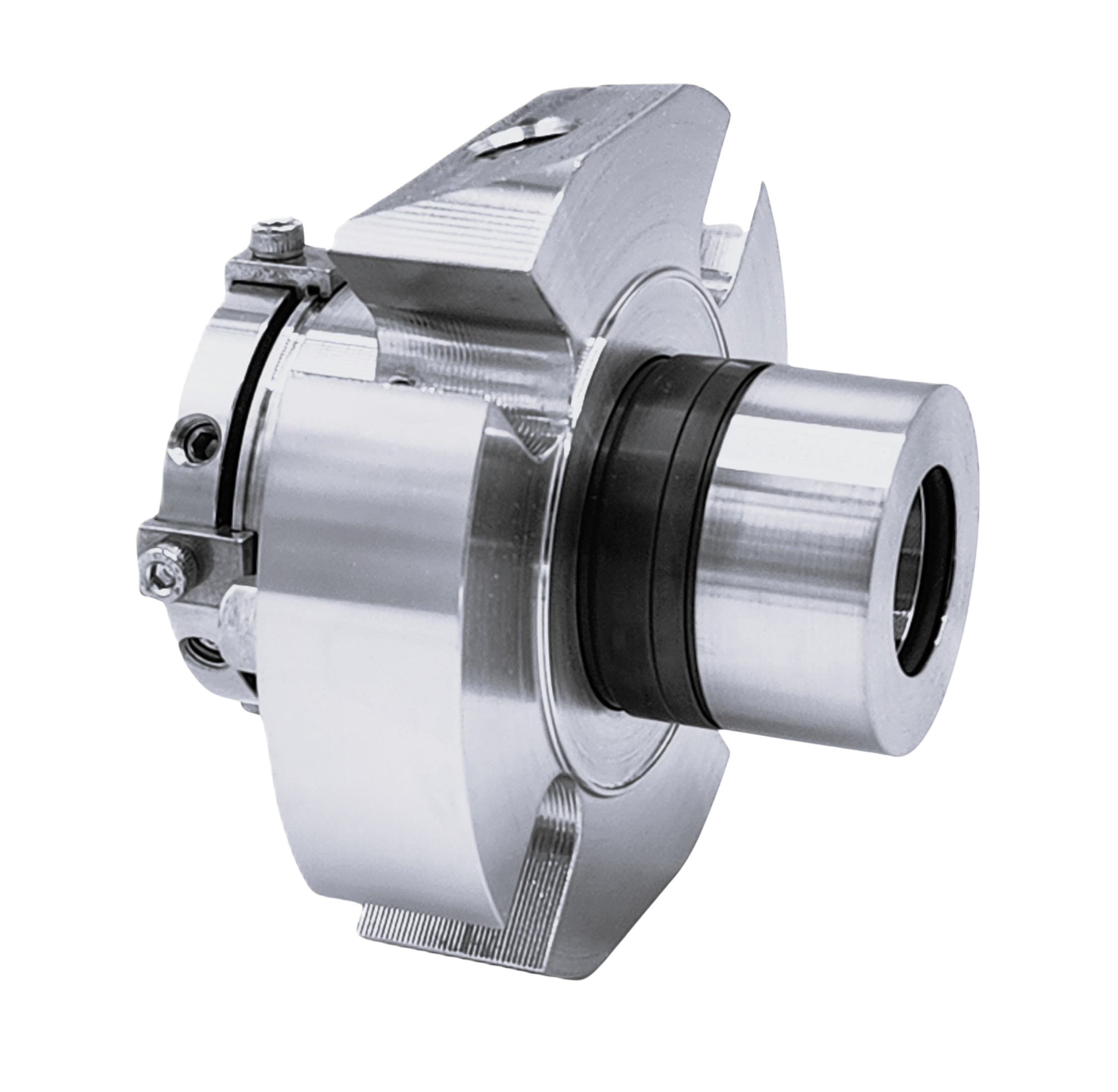

PRODUCT DESCRIPTION

* Dual Seal Configuration

* Balanced Design

* Independent of direction of rotation

* Cartridge construction

* Double pressure balanced

* Designed with integrated pumping device for increased

efficiency in circulation

* Special design available for eccentric screw pumps

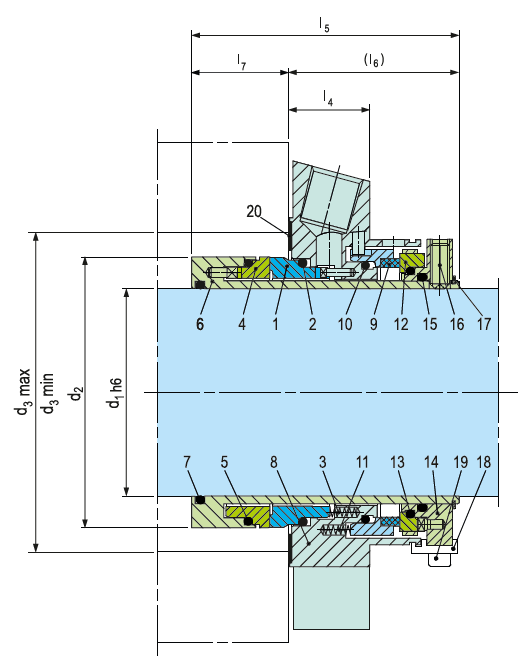

TECHNICAL FEATURES

* Ideal for use in process pump standardisation

* O-Ring is dynamically loaded to present shaft damage

* Dimensional modification of the stuffing box chamber is not required

due to short radial installation height

* Ideal to convert and retrofit pumps with packings and large volume

OEM production

* Cartridge unit factory assembled for easy installation, which reduces

downtime

* Rugged design for long operating life

Temperature: t = -40°C...+220°C (-40°F... +428°F)

Sliding Face Material Combination BQ1:

Pressure: p₁ = 25 bar (363 PSI)

Speed: = 16 m/s (52 ft/s)

Sliding Face Material Combination Q1Q1 or U2Q1:

Pressure: p₁ = 20 bar (290 PSI)

Speed: = 10m/s (33ft/s)

Barrier fluid circulation system:

P₃max = 25 bar (363 PSI)

Δp (p₃ - p₁) ideal = 2...3 bar (29...44 PSI), 7 bar (102 PSI) for barrier media with poor lubricating properties

Pump startup: Δp (p₃ - p₁) max = 25 bar (363 PSI) allowed Recommended supply medium: max. ISO VG 5

Permissible axial movement: ± 1.0 mm, d₁ ≥ 75mm ± 1.5mm

MATERIALS AVAILABLE

Seal Face: Silicon Carbide (Q1), Carbon graphite resin impregnated (B), Tungsten Carbide (U2)

Seat: Silicon Carbide (Q1)

Secondary Seals: Viton, EPDM, Kalrez, Perflourocarbon rubber/PTFE

Springs: Hastelloy® C-4 (M)

Metal Parts: CrNiMo Steel (G), CrNiMo Cast Steel (G)

PERFORMANCE CAPABILITIES